Melt Flow Index

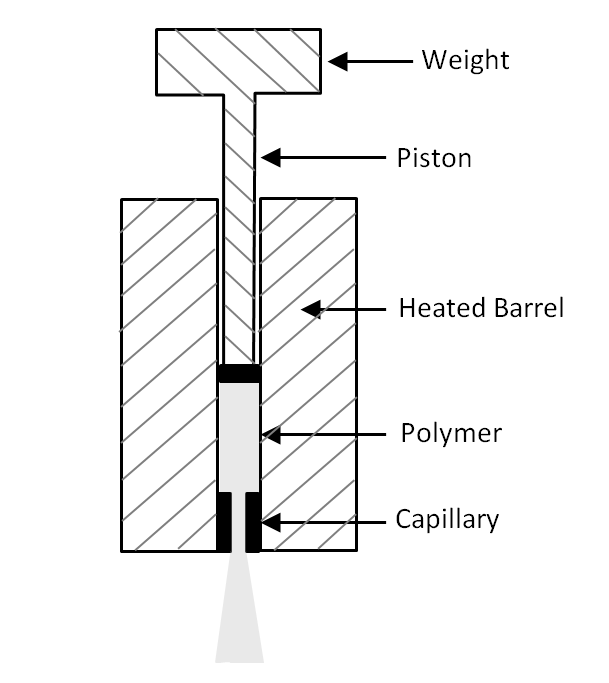

The melt flow index (MFI) or melt flow rate (MFR) is a measure for the ease of flow of melted plastics. It is often used in the plastic industry for quality control of thermoplastics. The method is described in the standards ASTM D1238 and ISO 1133. A small sample of about 5 grams is heated above its melting or softening point and forced to flow through a capillary using a piston actuated by a specified weight, usually 2.16 kg or 5 kg. The weight of melt in grams flowing through the capillary in 10 minutes is the melt flow index.

Melt Flow Indexer

Melt Flow Indexer

Melt flow indices are often listed on data sheets of thermoplastic materials. In general, a higher MFI indicates a lower material viscosity, and when comparing polymers of the same class, a lower melt flow rate corresponds to a higher molecular weight and/or less branching.

The melt flow indexer is the most popular device in the plastic industry to determine material viscosities and is often used to test batch-to-batch consistency. However, it is also the least accurate method. To obtain more accurate and meaningful viscosity data, a capillary or a cone and plate rheometer should be used. Some companies will also perform in-mold rheology tests using actual manufacturing molds.